Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Parts ProcessingSolutions

Based on professional evaluation, Jinholly provides the most competitive manufacturing solutions for clients.

Why Jinholly

With more than two decades of manufacturing experience, Jinholly custom metal shaping supplier offers superior manufacturing methods and metal shaping service like metal powder metallurgy and CNC milling and turning services, etc. for metal parts in various fields.

Jinholly's metal shaping service is recognized by professional clients. Providing professional and safe services is our main goal. In particular, Jinholly specializes in process integration to offer vertically integrated one-stop services for the upstream and downstream industries to meet the diverse needs of clients, help them reduce costs, and achieve high efficiency and quality services. For more metal shaping service inquiries, please contact us via forms.

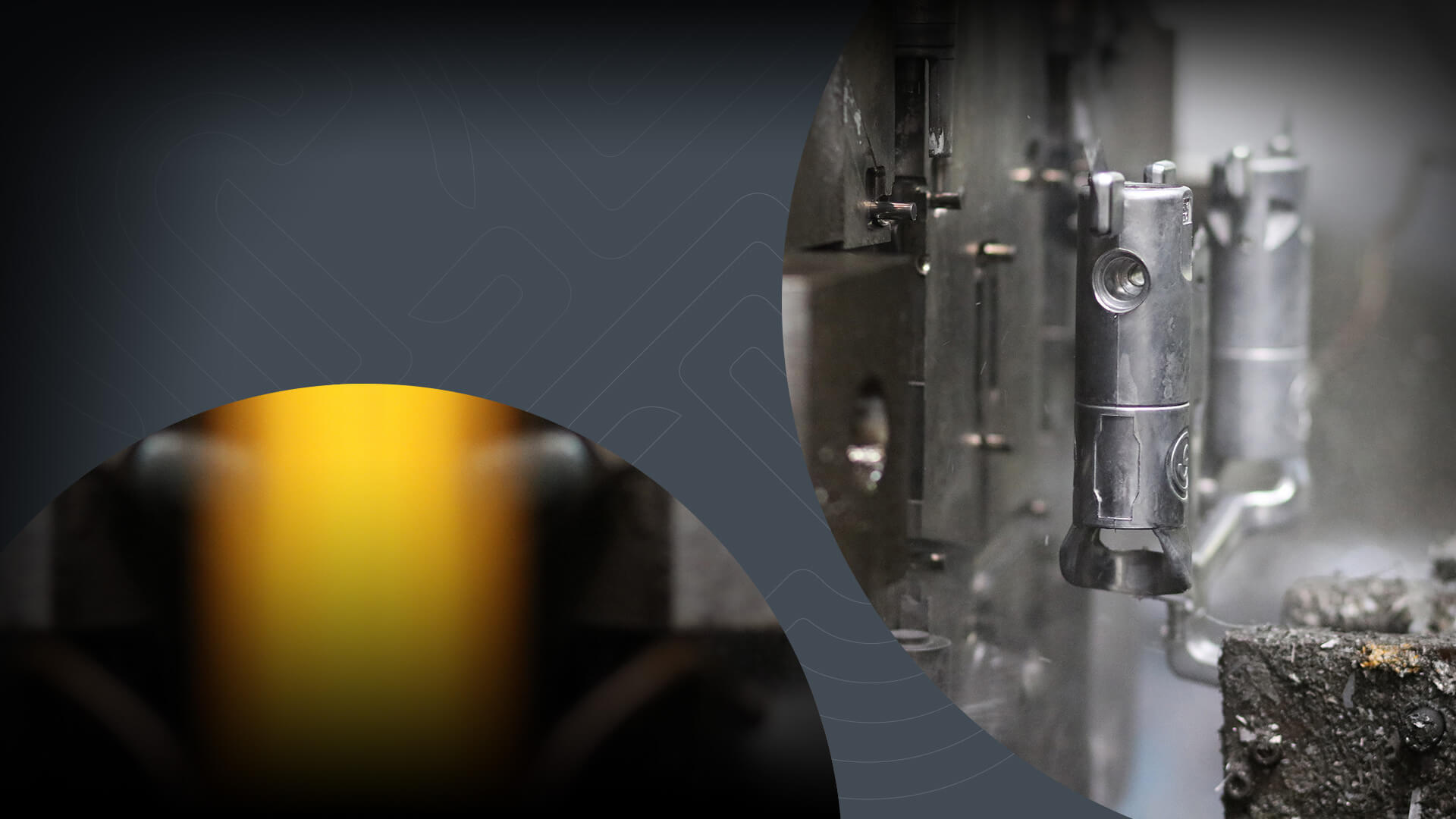

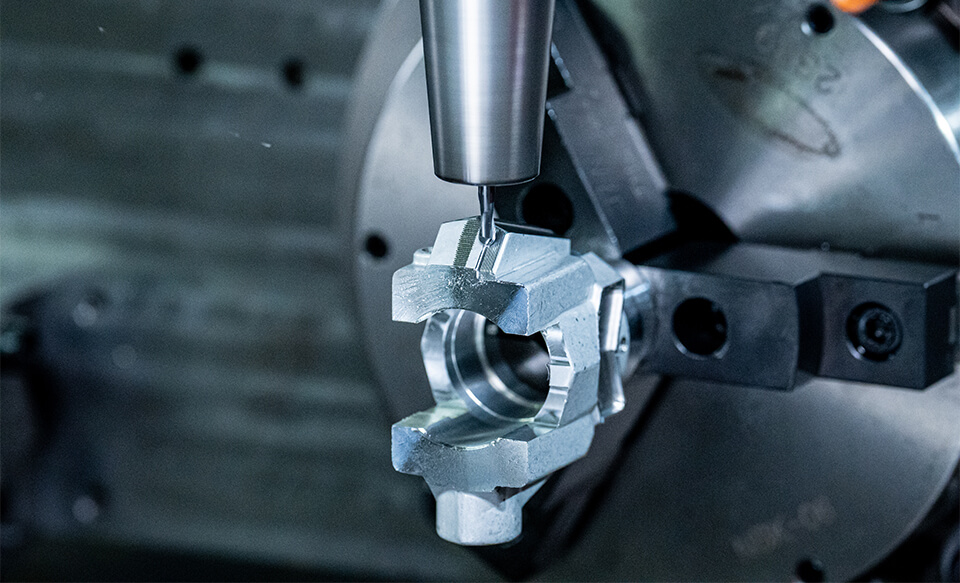

CNC Turning and Milling Service

Jinholly has milling and turning processing experience for many years. Design suitable fixtures through programming and precisely control the tolerance. Carry out lathe and milling machine processing according to the customer‘s drawing and also formulate the planning of the manufacturing process according to the customer's sample.

Lost Wax Casting

Lost wax casting is suitable for processing products with special shapes and high strength, which can effectively reduce manufacturing procedures. This technology can be used in almost all metal materials, and the required materials can be selected according to different needs, which avoids consuming metal materials, and achieves the purposes of short construction time and low cost.

Aluminum Alloy Processing

Jinholly can provide products requested by clients in accordance with physical structure, tolerance dimensions, and materials of finished products.

Aluminum alloy machining services like heat and surface treatment are available to achieve the optimal strength, impact resistance, fatigue resistance, and other excellent mechanical properties of the products.

Metal Forging

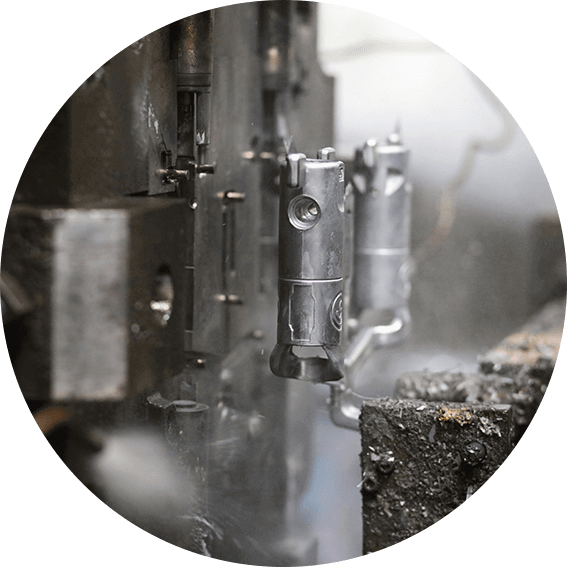

Alloy forgings shall be heated to a certain temperature before processing and then placed between molds and pressed into shape by a forging machine with certain gravity pressure, thus obtaining excellent mechanical properties such as maximum directional strength, impact resistance, and fatigue resistance.

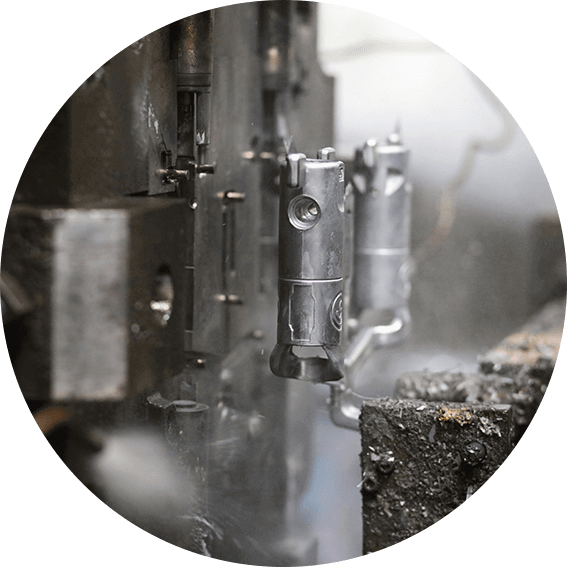

Metal Injection

Metal injection molding (MIM) is one of the metal shaping services Jinholly excels in. This technology combines powder metallurgy and injection molding to break through the limitations of traditional powder metallurgy in terms of product shape and strength of die-casting, as well as the constraints of precision casting in terms of mass production and high cost of CNC parts.

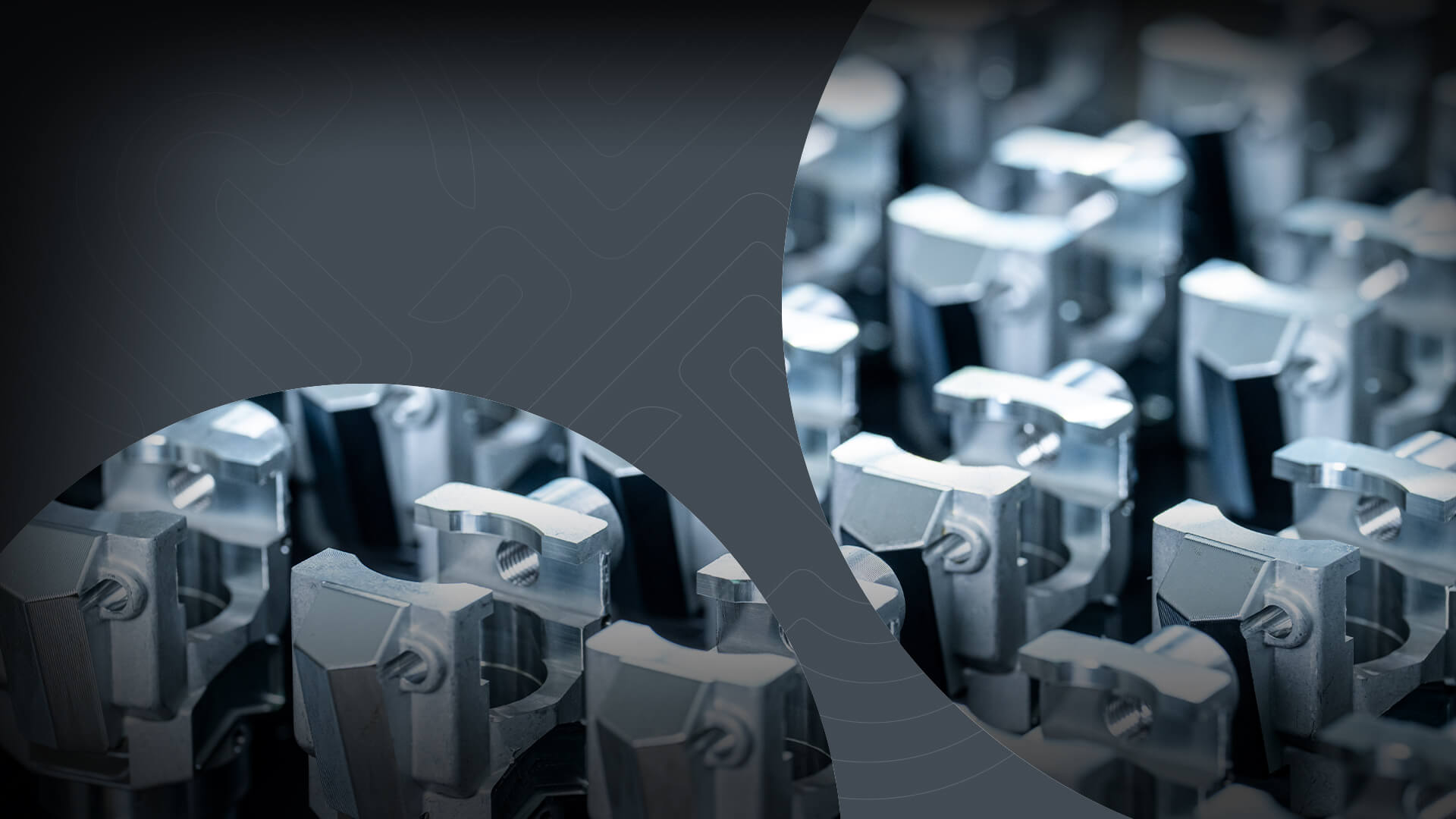

Powder Metallurgy

Powder metallurgy is suitable for a wide range of applications due to its simple processing steps, high material utilization rate, and high dimensional accuracy of the parts. Besides, with this method, the material composition can be adjusted according to the performance requirements of clients, and the use of mold forming can produce complex parts with peculiar shapes that cannot be produced by other cutting processes.

SERVICE

Processing Types

The manufacturing methods of custom metal shaping include aluminum alloy, metal injection, powder metallurgy, lost wax casting, custom metal forging, etc. Jinholly provides various metal shaping services and completes its one-stop services from materials to finished products.

Secondary Processing

Jinholly offers diversified additional services, such as CNC milling, CNC turning, surface treatment, heat treatment, and other processing services we can satisfy a diverse range of customer needs.

Solutions

According to the needs of clients, Jinholly provides professional and competitive solutions through our custom metal shaping service. Additionally, we integrate resources and conduct data and cost analysis for clients to create products with higher values.

OEM / ODM Solution

Select appropriate processing methods for clients to help them reduce costs, achieve high efficiency, and high-quality service.

-

No.243, Yongfeng Rd., Taiping Dist., Taichung City 411, Taiwan

-

886-4-22788676

- Designed by GTMC

- Taiwan Products

- B2BManufactures

- Market-Prospects