Lost Wax Casting Factory from Taiwan

Product Introduction

Lost wax casting makes it easy to carve the wax to make the product, and after the metal is cooled, the refractory clay is opened to obtain the final metal casting product. There are no restrictions on the materials used in casting. Our lost wax casting services are mainly used to produce stainless steel, carbon and alloy steel, low-alloy steel, aluminum alloy steel, and tool steel.

Lost wax casting is an ancient traditional process with a very long history. With the advancement of technology, this ancient process has been improved to meet the requirements of modern mass production.

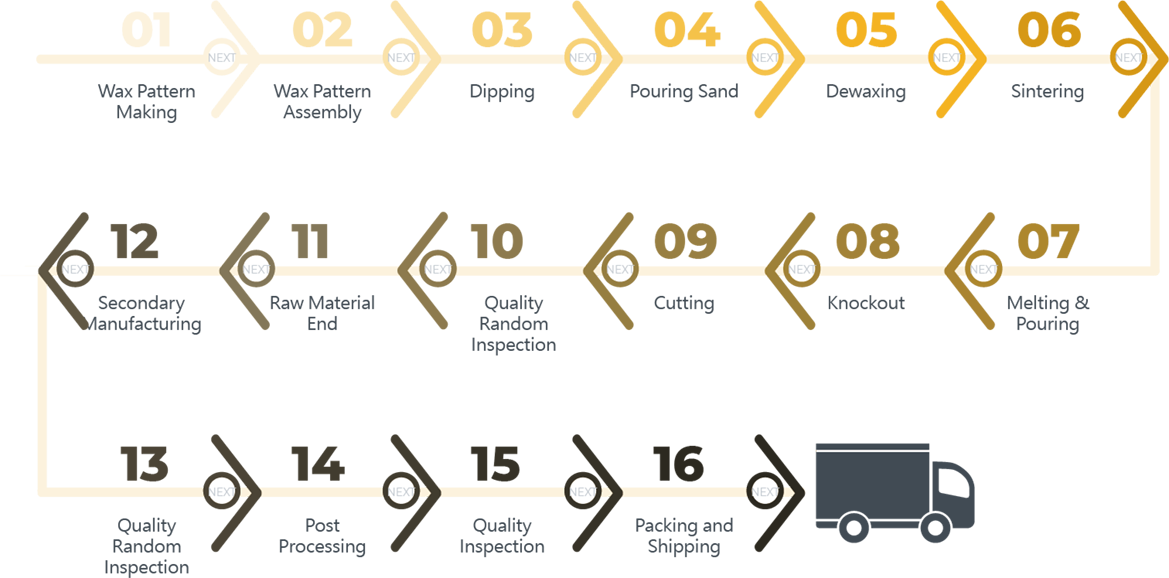

Simply put, lost wax casting adopts wax that can be easily sculpted and shaped to make the finished products, which are covered with refractory mortar, and with a small hole reserved for casting. After drying and hardening the refractory mortar, it will be processed at high temperatures, and the dissolved wax will flow out to leave a hollow in the refractory mortar. Then the molten metal liquid will be poured into the small hole to fill it. After the metal is cooled down, the final metal casting products will be obtained by knocking the refractory mortar. Lost wax casting adopts various materials without limitation. As a professional lost wax casting supplier, Jinholly mainly uses stainless steel, carbon and alloy steel, low alloy steel, chrome molybdenum alloy steel tool steel for lost wax casting.

Lost Wax Casting Supplier Who Can Meet Modern Mass Production

Advantages of lost wax casting:

- More than 90% of the precision casting parts produced by lost wax casting can be used without further machining, thus saving lots of costs.

- Lost wax casting can be used to make products with simple or complex shapes.

- Reduce processing and waste: As lost wax casting can be used to make products with complex shapes, it can simplify processing.

Jinholly lost wax casting supplier combines the upstream manufacturing of lost-wax materials, the midstream processing of lathes and milling machines, and the downstream surface treatment. By integrating the advantages of the manufacturing process, it has self-developed molds, evaluated the reserved amount and shape of the materials, and achieved the processing stability of the key points of clamping, thus stably controlling the sizes of lost-wax products. With profound experience and the advantages of high-end manufacturing equipment, Jinholly lost wax casting companies can provide customized products with the highest quality. Our commitment is to provide clients with the best quality and the most perfect lost wax casting services.

Sincerely welcome relevant buyers from all over the world to visit and cooperate.

OEM / ODM Solution

Select appropriate processing methods for clients to help them reduce costs, achieve high efficiency, and high-quality service.