Hand Tool

Jinholly not only provides clients with high-quality products but also assists them in developing new products in the ODM aspect. Taking the following example as an example, the workpiece is a core part of the nail gun, as the original process adopts lost wax casting, it needs to be processed on a variety of places, quite complicated, resulting in high cost and unable to meet clients' production capacity.

Solutions

The original method is lost wax casting, which needs to process on many places, resulting in high costs and insufficient production capacity that cannot satisfy the requirements of clients either.

Evaluation of Workpiece

Suggested Method

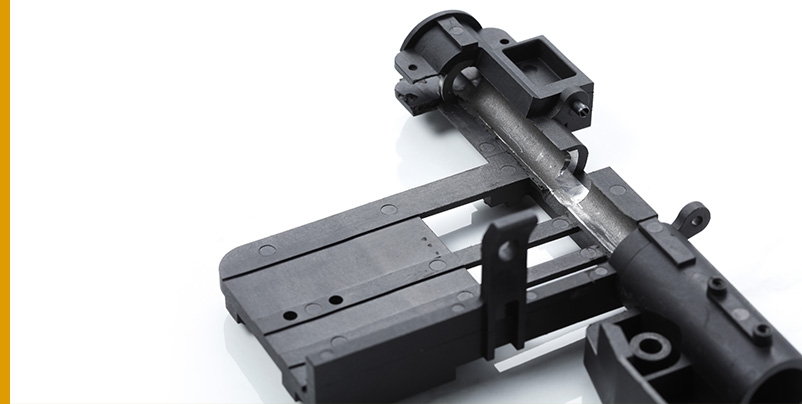

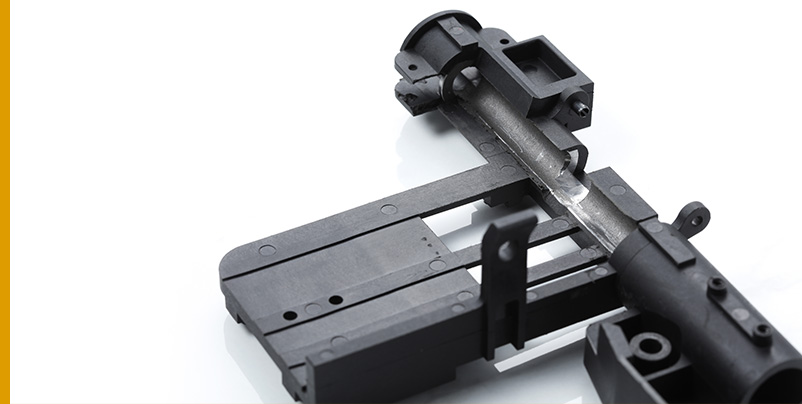

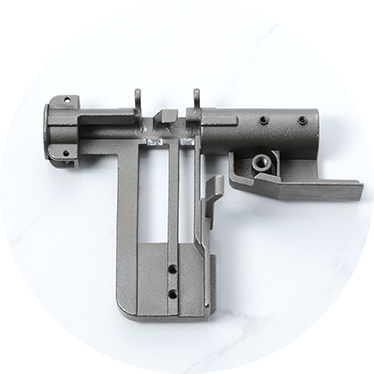

After understanding the overall functionality of the workpiece, we disassemble it into two parts, the core part which requires precision machining and the supportive parts which do not require machining, for clients to conduct the evaluation. Lathes and milling machines are used to make the tolerance of the core part of the gun meet the standard.

Reduce Costs

Speed Up the Delivery

The original supportive parts were originally processed by casting, and now they are changed to plastic injection molding, so as to reduce the weight and make the assembly smooth.

First Generation

Second Generation

Final Generation

OEM / ODM Solution

Select appropriate processing methods for clients to help them reduce costs, achieve high efficiency, and high-quality service.